Time is actually necessary in enterprise. Research say that 25% of consumers gained’t purchase one thing except it may be shipped in two days or much less. Understanding how essential time is for protecting prospects completely satisfied and influencing what they purchase, it’s clear that dealing with lead time (which suggests the time it takes to get issues prepared) is not only wanted for enterprise, however it additionally offers an edge in at the moment’s aggressive and sophisticated financial system. To make issues less complicated, having a transparent lead time definition helps in ensuring orders are fulfilled on time and prospects are glad.

With this in thoughts, we’ll discover on this weblog the definition of Lead Time, its impression, and the way mastering it may be your aggressive benefit.

Discovering Lead Time: A Easy Definition and Sorts

The search to reduce lead time will be traced again to the origins of Simply-In-Time (JIT) manufacturing, emphasizing the numerous impression of bottlenecks and lot sizing. Lead time, with various definitions primarily based on course of levels, primarily measures the time wanted to finish an operation, calculated because the end date minus the beginning date.

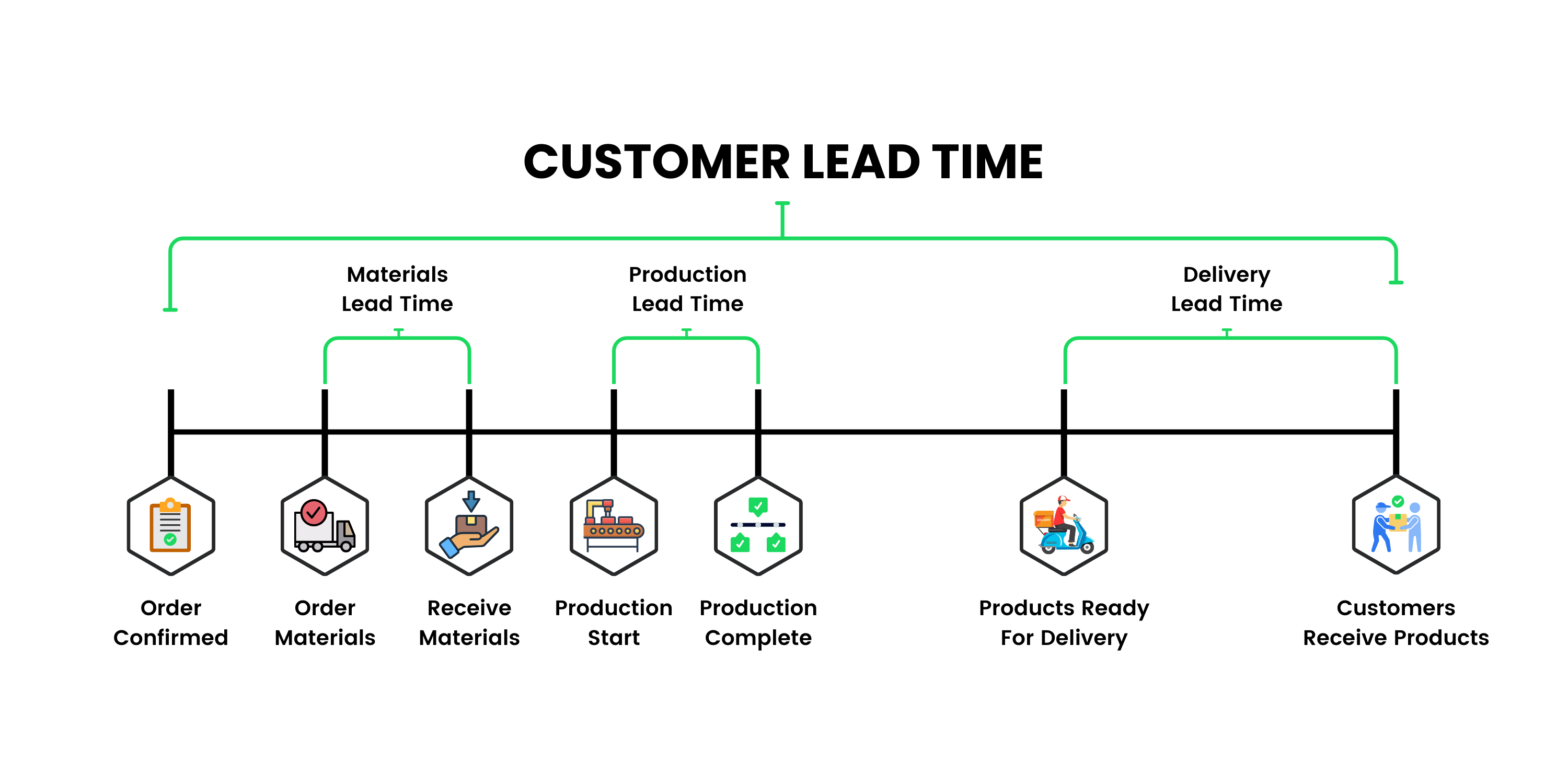

In provide chain administration, whole lead time is a vital metric encompassing the interval from buyer order to supply, be it in B2B or B2C situations.

This whole time will be additional categorized into key elements:

Procurement Lead Time:

This dimension, located within the upstream provide chain, covers the length from inserting an order to receiving it.

Manufacturing Lead Time:

Encompassing manufacturing, high quality management, meeting, and associated processes.

Supply Lead Time:

Within the downstream provide chain, supply lead time represents the time from order receipt to product supply, together with actions similar to packing and transportation.

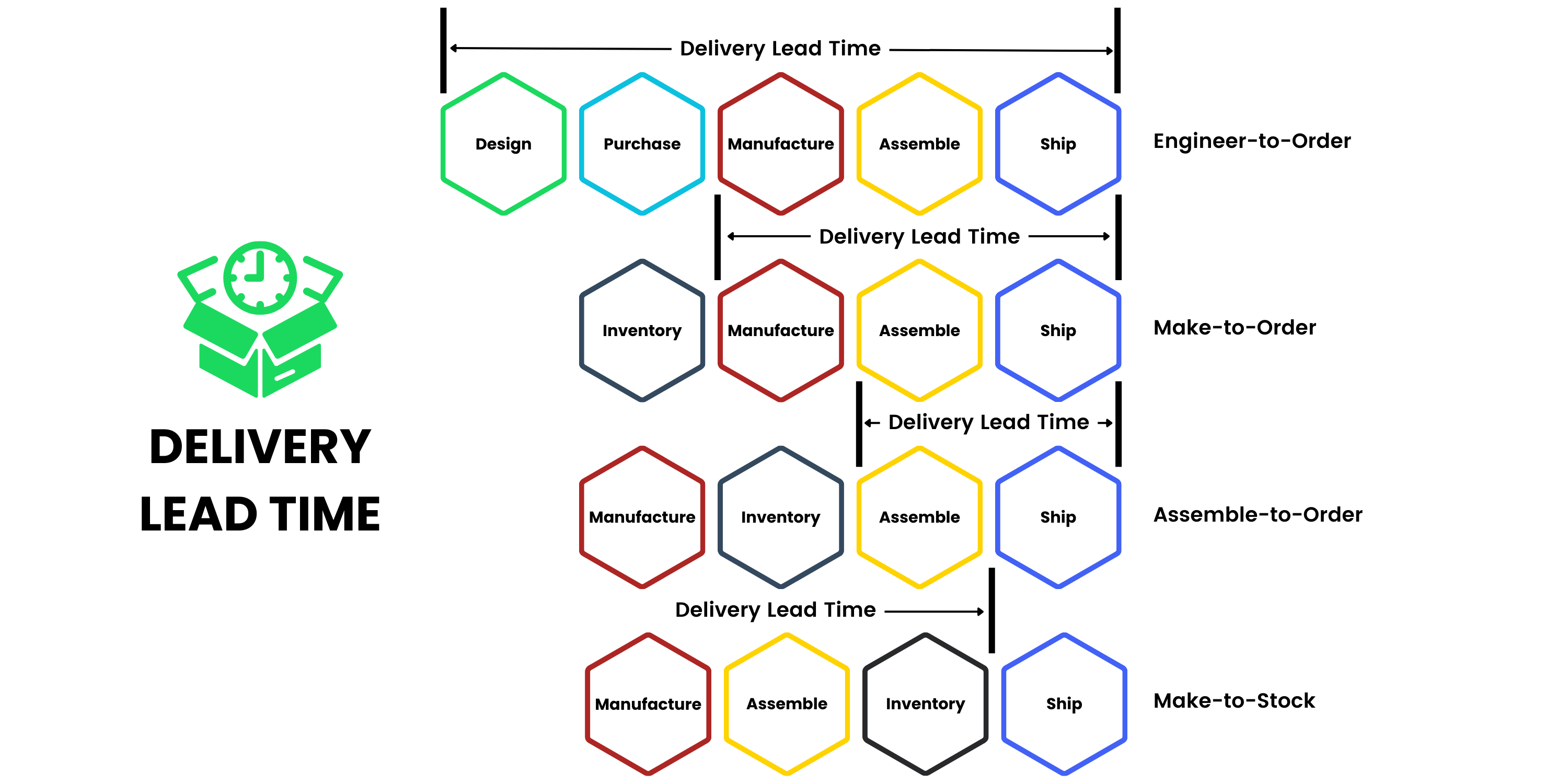

Relying on the chosen manufacturing technique (Make to Inventory, Assemble to Order, Make to Order, or Engineer to Order), the supply lead time might differ as follows:

Entry our weblog “6 Causes Why It Is Vital to Perceive Anticipated Buyer Lead Time” at our web site SCMDOJO!

Navigating the Influence: Uncontrolled Lead Time and Enterprise Penalties

Uncontrolled lead time can have direct adverse repercussions for a enterprise, leading to a decrease service degree, extra inventory, elevated variability, uncertainty, and extra prices. As a essential provide parameter, managing lead time is crucial for mitigating uncertainties within the provide chain. Based on the article “Modeling the flexibleness of order portions and lead-times in provide chains”, by Sanchoy Okay. Das and Layek Abdel-Malek : “most provide chains have solely restricted flexibility, and might solely accommodate “noise” degree uncertainties”.

Every sort of lead time can impression the worldwide course of.

Procurement Lead Time:

- Environment friendly procurement lead time ensures well timed entry to uncooked supplies, a elementary step towards environment friendly manufacturing.

Manufacturing Lead Time:

- Past decreasing carrying prices and stock ranges, an optimized manufacturing lead time empowers companies to reply rapidly to modifications in market demand.

- The agility achieved by manufacturing lead time optimization serves as a strategic benefit in an ever-evolving enterprise panorama.

Supply Lead Time:

- Companies should acknowledge the pivotal position of supply lead time in shaping the general buyer expertise and fostering model loyalty.

Complete Lead Time:

- The impression of lead time optimization extends to Return on Funding (ROI) and the overall effectivity of the whole group.

- An effectively managed whole lead time is a key issue for improved operational efficiency and sustained enterprise progress.

Learn extra on “Optimizing Stock and Lead Time Administration” at our Web site SCMDOJO!

Advantages of Lead Time Discount:

Lead time discount, which refers back to the time it takes to finish a course of from the initiation to the supply of the ultimate product, can provide numerous benefits to companies. Listed here are a few of the high advantages:

Improved Buyer Satisfaction:

- Quicker lead occasions imply faster supply to prospects.

- Assembly or exceeding buyer expectations for supply occasions enhances buyer satisfaction.

Elevated Flexibility:

- Shorter lead occasions make it simpler to adapt to modifications in buyer demand or market situations.

- Companies can extra rapidly modify manufacturing schedules or change product choices in response to market traits.

Diminished Stock Ranges:

- Shorter lead occasions allow companies to keep up decrease stock ranges.

- This will result in price financial savings by decreasing the necessity for space for storing, dealing with prices, and the chance of holding out of date stock.

Price Financial savings:

- Discount in stock holding prices.

- Improved effectivity in manufacturing processes and useful resource utilization.

Aggressive Benefit:

- Quicker lead occasions is usually a key differentiator in a aggressive market.

- Prospects usually choose companies with fast and dependable supply. Amazon has mastered this artwork, and everyone seems to be attempting to catch up!

Elevated Money Circulate:

- With decreased stock ranges, capital isn’t tied up in extra inventory.

- Quicker turnaround occasions may imply faster cost cycles.

Improved High quality Management:

- Shorter lead occasions permit for extra frequent high quality checks all through the manufacturing course of.

- Defects will be recognized and addressed earlier within the manufacturing cycle, enhancing general product high quality.

Enhanced Forecasting Accuracy:

- Shorter lead occasions make it simpler to forecast demand precisely.

- Improved forecasting contributes to higher general provide chain planning.

Leaner Processes:

- Lead time discount usually includes streamlining and optimizing processes.

- The deal with effectivity can result in the identification and elimination of waste in numerous levels of manufacturing.

Adaptability to Market Adjustments:

- Shorter lead occasions allow companies to reply rapidly to modifications in market traits, buyer preferences, or regulatory necessities.

- In easy phrases, it makes your provide chain extra agile to deal with market modifications.

Innovation and Product Growth:

- Diminished lead occasions can facilitate sooner innovation and time-to-market for brand new merchandise.

- Companies can keep forward of the competitors by bringing new and improved merchandise to market extra rapidly.

It’s necessary to notice that the advantages of lead time discount can differ primarily based on the particular business, product sort, and the general provide chain technique of the enterprise. Implementing lead time discount methods requires a cautious evaluation of current processes and collaboration throughout completely different levels of the availability chain.

Mastering Lead Time: Stabilization and Optimization Methods

The most typical mistake is trying to find how you can cut back the lead time earlier than attempting to stabilize it. The journey to steer time discount begins with understanding the prevailing lead time.

As a part of efficient provide chain administration, it’s important for firms to obviously distinguish between contractual lead time and precise lead time. Contractual lead time represents the agreed or anticipated interval for the completion of a specific course of, whereas precise lead time is the real-time taken to execute the method in observe. By figuring out and analyzing the hole between contractual and precise lead occasions, firms can achieve useful perception into current gaps. This consciousness is step one to figuring out and resolving particular points which will impression operational effectivity.

Upon getting tracked your precise lead time, you should stabilize it. Key steps on this course of embody:

Course of Evaluation:

- Conduct a radical evaluation of manufacturing and procurement processes to determine bottlenecks and inefficiencies.

- Focused course of enhancements can result in extra environment friendly operations.

Provider Transparency:

- Foster clear communication with suppliers to anticipate delays and proactively handle potential challenges.

- Collaborative relationships with suppliers contribute to a extra agile and responsive provide chain.

Security Inventory Administration:

- Keep an optimum degree of security inventory to mitigate variability and anticipate delays within the provide chain.

- Sensible security inventory practices assist defend in opposition to sudden disruptions.

After this step, firms can consider completely different actions to shorten it, similar to:

Home Provider Utilization:

- Interact home suppliers to considerably cut back lead occasions, particularly in situations the place abroad suppliers might contain prolonged supply intervals.

- Proximity to suppliers enhances the velocity of fabric acquisition, accelerating the general manufacturing course of.

Onshoring for Enhanced Service:

- Think about proximity to class A prospects to boost customer support charges.

- Onshoring methods contribute to a extra responsive provide chain, aligning with customer-centric enterprise approaches.

Optimized Order Frequency:

- Whereas there’s a conventional perception that inserting massive bulk orders is an economical technique, it’s essential to acknowledge that its suitability is determined by the context: Massive orders can certainly leverage economies of scale and optimize manufacturing prices, particularly in industries the place demand is comparatively steady. Nonetheless, it’s important to contemplate potential drawbacks. These embody elevated carrying prices, the chance of product obsolescence with prolonged storage, and the necessity for substantial monetary sources.

- Every business and enterprise state of affairs might require a tailor-made strategy to order sizing. If attainable, exploring the choice of inserting extra orders might be useful in decreasing lead occasions.

Vendor Managed Stock (VMI):

- VMI is a collaborative strategy to stock administration the place the seller or the provider, often the producer, is liable for replenishing the consumer’s inventory.

- VMI acts as a bridge between the consumer and the provider, permitting them to share real-time information. This visibility allows the seller to actively handle the customer’s stock ranges. Suppliers can anticipate demand and cut back replenishment occasions. This synchronization between provide and demand contributes on to decreasing the overall lead time.

Consignment Stock:

- Consignment Stock is when the provider shops stock on the buyer’s web site.

- It contributes to decreasing the lead time because the merchandise are already accessible, thus eliminating ordering and transport time.

Lean Manufacturing Rules:

- Lean manufacturing strategies deal with steady enchancment and promote effectivity all through the manufacturing chain.

- Implement lean manufacturing ideas to eradicate wasteful actions and streamline manufacturing. By figuring out and eliminating non-value-added actions, firms can optimize processes, cut back manufacturing cycle occasions, and in the end decrease lead occasions.

As you’ll have seen, though lead time is a traditional parameter regularly mentioned, taking efficient motion to stabilize and cut back it’s no easy job. However in the event you grasp these factors and act on them appropriately, the implications will be essential. Not satisfied? Let’s see some examples:

- By decreasing its lead time, Zara succeeded in altering the design of its clothes each two weeks, in comparison with its opponents’ common of two to a few months. This technique allowed the Spanish label to triple its earnings, develop its retailer community, and at present rank because the third-largest retailer.

- The quickest deliveries for Prime within the second quarter of 2023 helped Amazon seize a 3rd of U.S. on-line orders, six occasions greater than its greatest competitor Walmart.

- Dell, the market chief within the know-how sector, has successfully managed lead occasions by counting on Simply-in-Time Stock Administration.

Conclusion

In conclusion, understanding the significance of time in enterprise is essential. Environment friendly lead time administration goes past a enterprise necessity; it supplies a strategic benefit in at the moment’s aggressive financial system. Exploring the lead time definition turns into important for navigating order achievement complexities and guaranteeing buyer satisfaction. On this weblog, we’ve delved into the definition of lead time, its impression on enterprise, and the way mastering it may be a aggressive benefit.

By decreasing lead time, companies can expertise advantages like improved buyer satisfaction, elevated flexibility, and price financial savings. The journey to steer time discount includes stabilizing processes, optimizing order frequency, and embracing lean manufacturing ideas. In the long run, mastering lead time isn’t a easy job, however the constructive penalties will be transformative for companies, as exemplified by success tales from Zara, Amazon, and Dell.

Concerning the Creator – Ikram Ahjiej

My title is Ikram Ahjiej. I studied Industrial Engineering at Ecole Nationale des Mines de Rabat. Presently, I’m pursuing an Superior Grasp’s in International Provide Chain Administration at KEDGE Enterprise Faculty, and I’m apprenticing at Danone in Buyer Service.

Ceaselessly Requested Questions:

Q: What do you imply by lead time?

Ans: Lead time is the overall length from order initiation to completion, overlaying all intermediate steps.

Q: What’s the which means of time to steer?

Ans: It sometimes refers back to the length it takes for a corporation or product to ascertain a number one place out there.

Q: Why is it known as lead time?

Ans: The time period possible comes from the concept that lead time precedes the precise supply, offering an estimate for planning and execution.

Q: What’s lead time vs supply time?

Ans: Lead time consists of the whole course of length, whereas supply time particularly focuses on the length between cargo and arrival on the vacation spot.